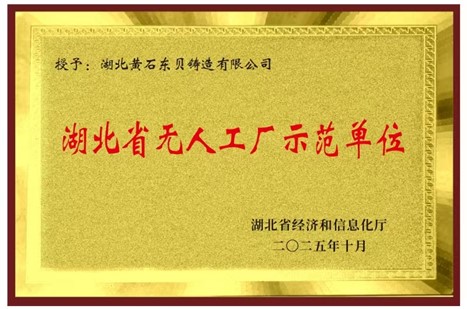

Huangshi Dongbei Casting has been awarded as a demonstration unit for unmanned factories in Hubei Province

Recently, Huangshi Dongbei Casting Co., Ltd. (hereinafter referred to as "Huangshi Dongbei") applied for the "250000 ton precision material unmanned manufacturing and processing project", which passed the strict review of the entire process by the Hubei Provincial Department of Economy and Information Technology, and successfully won the title of "Hubei Province Unmanned Factory Demonstration Unit". As the first factory level unmanned factory in the casting industry in the province, the implementation of this project not only fills the technological gap in the intelligent upgrading of the regional precision casting industry, but also sets a benchmark for the development of "new quality productivity" in the manufacturing industry through the "smart manufacturing+green" dual wheel drive model, injecting strong momentum into the construction of a strong manufacturing province in Hubei Province.

Breaking through the impasse: Strategic investment of 1.5 billion yuan to build the cornerstone of intelligent production

It is reported that the total investment of the "250000 ton precision material unmanned manufacturing and processing project" has reached 1.5 billion yuan, and the current phase of the project has completed a phased investment of 600 million yuan, focusing on two core areas to lay a solid foundation for the construction of unmanned factories:

Intelligent hardware cluster investment of 400 million yuan: introducing internationally leading automated production lines, intelligent control systems, and digital twin platforms to achieve unmanned operation of the entire process from raw material processing, melting and casting to precision machining, with equipment automation rate of over 95% and production efficiency increased by 30% compared to traditional modes;

Green production system investment of 50 million yuan: deploying energy-saving and emission reducing intelligent equipment, waste gas and wastewater recycling treatment system, and clean energy supply network, reducing unit product energy consumption by 20%, pollutant emissions by 40%, and taking the lead in achieving ultra-low emission standards in the foundry industry.

The project takes "full process automation, full data interconnection, and full scene green" as the core operation paradigm, realizes real-time collection and analysis of production data through the industrial Internet platform, builds an integrated intelligent decision-making chain of "raw materials production detection logistics", and creates a new path of "unmanned+green" collaborative development in the field of precision casting.

Innovation Leading: Reshaping Industry Standards in Three Dimensions, Defining Practical Samples of "New Quality Productivity"

As the "first crab eater" in the intelligent transformation of the foundry industry in Hubei Province, the innovative value of Huangshi Dongbei Unmanned Factory is reflected in three dimensions:

1. Technological Breakthrough: A Paradigm Revolution from "Artificial Dominance" to "Intelligent Closed Loop"

The project breaks the bottleneck of traditional casting relying on manual operation, and realizes the unmanned closed loop of the whole process of "raw material incoming smelting forming precision machining finished product delivery" through the integration of 5G+industrial Internet, AI visual inspection, AGV intelligent logistics and other technologies. The precision control of key processes has reached ± 0.02mm, and the product qualification rate has been increased to 99.5%, which is 8 percentage points higher than the industry average, redefining the quality standards of precision casting.

2. Data driven: Building a "digital twin factory" to achieve full factor collaborative optimization

Relying on a fully interconnected data system, the project aims to create a digital twin model that covers design, production, and operation. It can simulate production scenarios in real time and predict equipment failure rates, increasing overall equipment efficiency (OEE) to 80% and shortening order delivery cycles by 40%. The deep application of data assets promotes the transformation of enterprises from "experience decision-making" to "data decision-making", providing a replicable technological framework for the intelligent upgrading of the industry.

3. Green Symbiosis: Sustainable Development Path under the Goal of "Zero Carbon Factory"

The project is supported by a 50 million yuan investment in environmental protection, integrating technologies such as waste heat recovery, comprehensive dust control, and water resource recycling. It reduces carbon emissions by 12000 tons annually and achieves a water resource reuse rate of 95%. It has been awarded the title of "Hubei Province Green Factory Demonstration Project". The collaborative model of "intelligent manufacturing+green production" provides a practical and feasible path for the manufacturing industry to achieve the "dual carbon" goal.

Industry radiation: From "single point breakthrough" to "ecological co construction", leading the intelligent transition of the industrial chain

The landing of unmanned factories is not only a milestone in Dongbei's own transformation, but also an 'engine' to promote the coordinated upgrading of the regional casting industry chain, "said the general manager of Huangshi Dongbei Casting Co., Ltd. After the project is completed, it has attracted three upstream and downstream enterprises to settle in the industrial park, and through shared intelligent logistics, testing platforms and other infrastructure, it has driven the overall production efficiency of the industrial chain to increase by 25%.

As a "demonstration unit for unmanned factories" recognized by the Hubei Provincial Department of Economy and Information Technology, Huangshi Dongbei's practice has become a "reference frame" for the intelligent transformation of the manufacturing industry in the province. The relevant person in charge of the Provincial Department of Economy and Information Technology commented, "This project fills the technological gap in factory level unmanned production in the casting field. Its' hardware+data+green 'integrated construction model provides important reference for the transformation of traditional manufacturing industries in the province towards' new quality productivity'

Future outlook: Deeply cultivating "intelligent manufacturing+industrial chain collaboration" to help build a strong manufacturing province

Facing the future, Huangshi Dongbei plans to further build an ecosystem of "intelligent manufacturing+industrial chain collaboration" with unmanned factories as the core: Phase II will invest 900 million yuan, focusing on building an industry level industrial Internet platform, promoting data exchange and capacity sharing between upstream and downstream enterprises; Simultaneously establish a precision materials research and development center, tackle key casting technologies in high-end fields such as aerospace and new energy, and strive to increase the revenue share of high-end products to 60% within three years.

We will continue to explore the technological boundaries in the field of precision casting with the posture of 'smart manufacturing benchmark', and contribute the 'Dongbei Plan' to building a national advanced manufacturing cluster in Hubei Province. "General Manager Lu Fengchong's words demonstrate the determination of the enterprise to drive high-quality development with innovation.

The landing of Huangshi Dongbei's "250000 ton precision material unmanned manufacturing and processing project" is not only a milestone in the intelligent revolution of Hubei's foundry industry, but also a vivid reflection of the accelerated rise of China's manufacturing industry's "new quality productivity". From "manufacturing" to "intelligent manufacturing", from "single point breakthrough" to "ecological leadership", Dongbei is writing a wonderful chapter in the construction of a strong manufacturing province in the new era with practical work and innovation.